Beschrijving

Genox Recycling Tech Co., Ltd.

Tire Recycling Machine, Shredder, Granulator manufacturer / supplier in China, offering Scrap Metal Shredding & Recycling System /Plant, Gsw Centrifugal Dryer/Centrifuge Dewatering Machine, Gxc Series Heavy Duty Granulator/Crusher and so on.

METAL SCRAP RECYCLING SYSTEM

GENOX METAL RECYCLING TECHNOLOGY

Our Advanced Metals Recycling Plants Are Often Installed At Scrap Metal Recycling Facilities

for The processing Of Various Different Metallic Waste Streams. Typical Applications For These

robust, Maintenance Friendly Systems Includes; Light Iron Scrap, ELV's (vehicle Shells And

body Panels), steel Drums, White Goods(refrigerators, Washing Machines Etc. ) Electronic

scrap & Computer Waste (WEEE/E- Waste), And Various Other Metal Containing Materials. Following The Pre-shredding Stage, The Shreds Are Further Reduced In Size And Densified By The Vertical

Shredder. During This Process Non-ferrous And Non-metallic Materials Are Liberated Allowing Them To Be Effectively Separated. Drum Magnets

and Eddy Current Separators (where Required) Sort The Shredded Product Into Their

respective Categories-ferrous, Non-ferrous & Non-metallics. The Resulting Steel Frag Product Is Both Clean And Compact With A High Bulk

density, Which Is Ideal For Sale And For minimising Transportation Costs.

About XENO Series Two Shaft Shredder

XENO Series Twin Shaft Shredders Are Extremely High Torque, High Throughput Shear Type

size Reduction Machines Often Used For Pre-shredding Of Large Volume Or High Strength Materials Which May Contain Contamination.

The Unique Modular Split Chamber Design, Provides Excellent Access To Key Components

therefore Reducing Maintenance Downtime And Service Costs Which Is A Huge Advantage

when Comparing Machines Of This Size.

About OZMA Series Vertical Shredder

OZMA Vertical Shredders Are Mainly Applied In Applications Processing Pre-shredded Metal Scrap From Twin Shaft Shredding Systems. These Machines Aggressively

size Reduce And Densify Pre-shredded Material Whilst Liberating The Various Different Fractions And Allowing For Better

separations And Reduced Transport Costs, The Breakers In The Upper Part Of The Chamber

smash The Material Until It Is Small Enough To Enter The Gap Between The Milling Rings And

chamber Liners. When The Material Enters The Second Stage The Milling Rings Impact,

grind And Roll The Material Into Clean Fragments. When Milled In To Small Enough Pieces,

the Balled Up Material Falls Into The Lower Chamber. It Is Then Ejected By The Discharge

paddle. The Three Above Stages Crate A Product Which Is Both Clean And Of High Bulk

density Suitable For Transportation.

Prior To Delivery From Our Facility, All Our Scrap Metal Recycling Systems Are Set Up And

tested Under " Real World" Conditions To Ensure The Plant Capacity And Quality Of The Finished

products Is Guaranteed. Customers Are Welcomed And Encouraged To Attend These Trials

to See Their Plant In Operation, Receive Training On The Operation And Maintenance Of Their

system, And To See Similar Equipment In Build.

A typical Metal Recycling System properly including machines as below:

Steel Hinged Belt Conveyor

Suitable For The Conveying Heavy, Sharp, Difficult To Handle Materials In Extremely

demanding Working Environments.

Twin Shaft Shredder

High Torque, Slow Speed Shredding Of The Input Materials Into Manageable Strips, Typically

100mm Wide X 300mm Long, Suitable For Further Processing In Downstream Equipment.

Vertical Shredder

For The Aggressive Size Reduction And Densification Of Pre-shredded Materials Into Into

50-80mm Pieces, During This Shredding Process The Material Is Sheared, Crushed, Rolled And

smashed, Creating A Clean, Dense, Steel Frag Product, Whilst Also Liberating Other Materials

to Allow For Effective Separations.

Central Dust Control System

Dust And Fines Created During The Shredding Process Are Extracted To A centralized Filtration

system Through A Series Of Ducting.

Ferrous Metal Discharge

Separated Ferrous Material From The Magnet System Is Conveyed To A Single Discharge Point

Non-Metallics Discharge

Non-metallics Material Is Conveyed To A Drum Screen(trommel) And Can Be Segregated Into

< 25mm, 25-50mm & 50mm+ Fractions.

Eddy Current Separator

The Non Magnatic Materials Are Conveyed To The ECS Rotor At A Controlled Rate. The

material Is Separated By A Diverter Plate Into Non-ferrous (aluminium, Copper & Brass)&

non-metallic Fractions (plastics Etc. ). These Products Can Either Be Sold As Is, Or Be Further

processed And Upgraded To Increase Their Value.

Company profile

Genox is a combined word of " Generating Oxygen" With a meaning of creating a better environment through new and innovative technology. Both the employees and management of Genox abide by this principle and constantly pursue the most effective, reliable and cost-effective solutions for the recycling of waste materials.

Through extensive testing, seeking feedback from our valued customers and distributors, and working closely with our European engineering partners. Genox has developed an extensive range of technically advanced machinery for the processing of plastics, tires, and E-waste.

Plastics shredding, granulation, and washing systems, including complete recycling plants, are the important part of the Genox product range. Single shaft shredders, two shaft shredders, granulators, washing tanks, dewatering centrifuges and other necessary equipment which can be customized on request allows us to offer bespoke proposals tailored to suit the requirements of each and every customer.

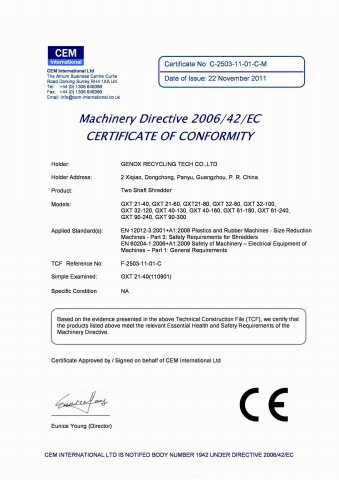

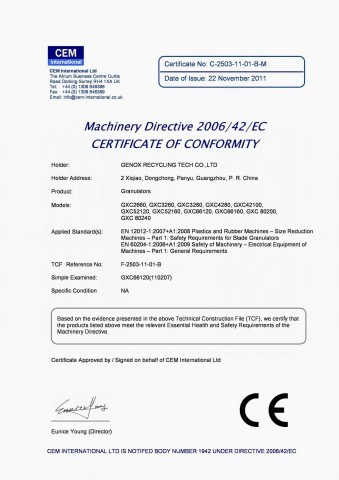

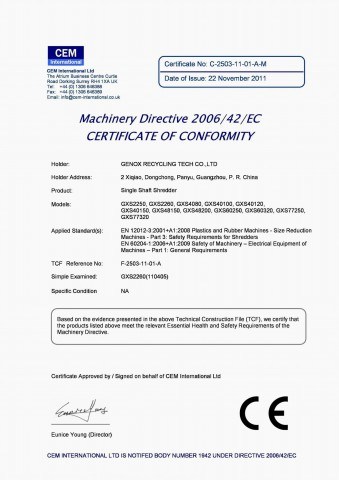

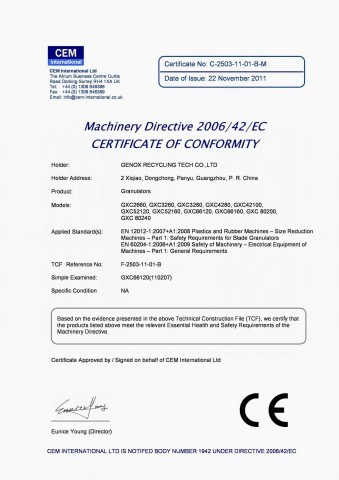

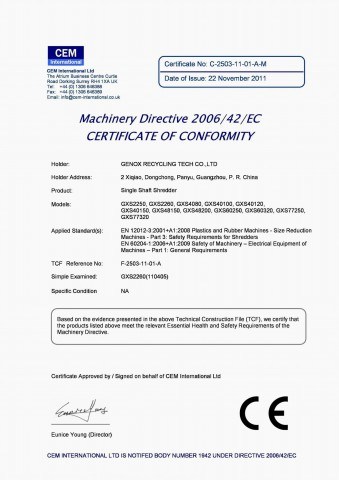

Certification

We awarded 50 utility model patents and 3 invention patents.

FAQ

1. Question: Will we provide pre-sale services?

Answer: Genox consists of experienced specialists, we will offer a suitable solution according

Client's requirement in time.

2. Question: Is our after-sales service excellent?

Answer: Genox's skilled technicians are available to assist with onsite installation,

commissioning & Training on request. This will enable customers to optimize the performance of

their new plant. Customers will be briefed on all aspects relating to operation and maintenance

by a Genox technician. Dimensional drawings together with service requirements will be provided

prior to delivery of the equipment. This will allow the customer to prepare the site and allow

them to commence production in a timely fashion.

Genox holds a adequately inventory of spare parts and their efficient service personnel will

ensure that any required part will be dispatched without delay. Delivery Of the spare parts

may be by air, sea or courier depending on the urgency of the situation. Customers are

encouraged to hold their own critical spare parts such as granulator blades and screens to

ensure optimal machine condition and performance.

3. Question: Will we provide technical support?

Answer: Genox provides enough hardware resource especially for large-scale production lines,

clients can carry out installation, commissioning and acceptance before delivery.

Main products

1. Plastic Shredder

2. Wood Shredder

3. Tire Shredder

4. Dead Animal Shredder

5. Household Refuse Shredder

6. Kitchen Garbage Shredder

7. Tyre Shredder

8. Crusher Shredder

9. Scrap Shredder

10. Auto Tire Shredder

11. Cold Dead Cow Shredder

12. Medical Waste Shredder

13. Plastic Recycling Shredder

14. PCB Shredder

15. Steel Scrap Shredder

16. Foam Shredder

17. Rubber Shredder

18. Drum Shredder

19. Lumps Shredder

20. Film Shredder

21. Jumbo Shredder

22. Woven Bags Shredder

23. Four Shaft Shredder

24. Double Shaft Shredder

21. Plastic Pipes Shredder

22. Plastic Film Shredder

23. Waste Injection Products Shredder

24. Plastic Bottles Shredder

25. Plastic Bags Shredder

26. Copper Tube Shredder

27. Tire Recycling System

28. Scrap Metal Recycling System

29. Cable/Electrical Wire Recyling System

30. WEEE Recycling System

31. Plastic Wshing & Dewatering Machine

32. Plastic Washing System

33. Plastic Granulator

34. Wood Granulator

Contact Detail:

Telephone: 86-20-66851346

Fax: 86-20-66851347

Address: Xiqiao, Dongchong Panyu, Guangzhou, Guangdong, China 511453

Welcome to contact us at any time We will reply you within 24 hours

Genox is a combined word of " Generating Oxygen" With a meaning of creating a better environment through new and innovative technology. Both the employees and management of Genox abide by this principle and constantly pursue the most effective, reliable and cost-effective solutions for the recycling of waste materials.

Through extensive testing, seeking feedback from our valued customers and distributors, and working closely with our European engineering partners. Genox has developed an extensive range of technically advanced machinery for the processing of plastics, tires, and E-waste.

Plastics shredding, granulation, and washing systems, including complete recycling plants, are the important part of the Genox product range. Single shaft shredders, two shaft shredders, granulators, washing tanks, dewatering centrifuges and other necessary equipment which can be customized on request allows us to offer bespoke proposals tailored to suit the requirements of each and every customer.

Certification

We awarded 50 utility model patents and 3 invention patents.

FAQ

1. Question: Will we provide pre-sale services?

Answer: Genox consists of experienced specialists, we will offer a suitable solution according

Client's requirement in time.

2. Question: Is our after-sales service excellent?

Answer: Genox's skilled technicians are available to assist with onsite installation,

commissioning & Training on request. This will enable customers to optimize the performance of

their new plant. Customers will be briefed on all aspects relating to operation and maintenance

by a Genox technician. Dimensional drawings together with service requirements will be provided

prior to delivery of the equipment. This will allow the customer to prepare the site and allow

them to commence production in a timely fashion.

Genox holds a adequately inventory of spare parts and their efficient service personnel will

ensure that any required part will be dispatched without delay. Delivery Of the spare parts

may be by air, sea or courier depending on the urgency of the situation. Customers are

encouraged to hold their own critical spare parts such as granulator blades and screens to

ensure optimal machine condition and performance.

3. Question: Will we provide technical support?

Answer: Genox provides enough hardware resource especially for large-scale production lines,

clients can carry out installation, commissioning and acceptance before delivery.

Main products

1. Plastic Shredder

2. Wood Shredder

3. Tire Shredder

4. Dead Animal Shredder

5. Household Refuse Shredder

6. Kitchen Garbage Shredder

7. Tyre Shredder

8. Crusher Shredder

9. Scrap Shredder

10. Auto Tire Shredder

11. Cold Dead Cow Shredder

12. Medical Waste Shredder

13. Plastic Recycling Shredder

14. PCB Shredder

15. Steel Scrap Shredder

16. Foam Shredder

17. Rubber Shredder

18. Drum Shredder

19. Lumps Shredder

20. Film Shredder

21. Jumbo Shredder

22. Woven Bags Shredder

23. Four Shaft Shredder

24. Double Shaft Shredder

21. Plastic Pipes Shredder

22. Plastic Film Shredder

23. Waste Injection Products Shredder

24. Plastic Bottles Shredder

25. Plastic Bags Shredder

26. Copper Tube Shredder

27. Tire Recycling System

28. Scrap Metal Recycling System

29. Cable/Electrical Wire Recyling System

30. WEEE Recycling System

31. Plastic Wshing & Dewatering Machine

32. Plastic Washing System

33. Plastic Granulator

34. Wood Granulator

Contact Detail:

Telephone: 86-20-66851346

Fax: 86-20-66851347

Address: Xiqiao, Dongchong Panyu, Guangzhou, Guangdong, China 511453

Welcome to contact us at any time We will reply you within 24 hours